IDT-Profile FD 30 IDT-Profile FD 30 |

IDT-Profile WD 60 IDT-Profile WD 60 |

|

Designs Designs |

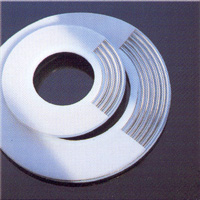

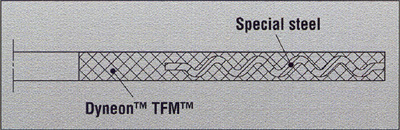

High-quality PTFE/Steel compound seal with 5㎜ wide diffusion stop and optimised

special steel corrugated ring inserts. The compound components are so matched

to each other that these results in excellent characters with regard to the

sealing technology. The Dyneon™TFM™ 1600 which is used as a much lower deformation

rate when subjected to pressing than conventional PTFE, even when subjected

to high temperatures whilst the structure which has a low number of pores reduces

the gas permeability. |

|

The special steel corrugated ring occludes the PTFE, resulting in a high

level of blow-out certainty and reduces the diffusion cross section of the seal.

The diffusion stop which is positioned in the interior diameter minimises

the leakage rate further and protects the corrugated ring against corrosion

resulting from the media. |

|

Areas of Use Areas of Use |

|

The main areas of use are there where a high level of safety standards are

required when sealing highly corrosive, hazardous and toxic media, with the

realisations of relatively low surface pressures, as well as such sensitive

areas as the lacquer, paints, pharmaceutical and food industries. The vacuum

is reliably controlled.

The users are provided with detailed assembly instructions and if they should

so require, calculations concerning the design of the sealing connections |

Technical Parameters Technical Parameters

бvu0.1 : |

8 N/㎟ |

бvu0.001 : |

17 N/㎟ |

бvu0.01 : |

10 N/㎟ |

бv0 : |

150 N/㎟ |

Gas permeability (DIN 28090, T.1) : |

<0.0001mg/s·m |

max. continuous temperature : |

250℃ |

max. working pressure : |

40 bar (at 250℃) |

The seal design is available in the nominal sizes DN 10 - DN 200, PN 40.

Release of Dyneon™TFM™1600 :

|

Corresponds with the Code of Federal Regulations Title 21 § 177.1550

"Perfluorocarbon resins" Corresponds with the Code of Federal Regulations Title 21 § 177.1550

"Perfluorocarbon resins"

of the FDA

Federal Institute for Materials Testing (BAM) approval for liquid oxygen Federal Institute for Materials Testing (BAM) approval for liquid oxygen

|

|

PTFE-silk Ribbon Vessel용 Gasket PTFE-silk Ribbon Vessel용 Gasket |

|

Design and Characteristics : Design and Characteristics : |

Concentric tubular braid of pure PTFE-silk, with PTFE and

lubricant impregnation.

Non-ageing, long service life, prevents flange corrosion. Physiologically generally

recognized as safe for food and pharmaceutical industries. |

|

Design and Characteristics : Design and Characteristics : |

|

| Concentric tubular braid of pure PTFE-silk, with PTFE and lubricant impregnation.

Non-ageing, long service life, prevents flange corrosion. Physiologically generally

recognized as safe for food and pharmaceutical industries. |

Application : Application : |

|

| Vessels and flanges with big dents on the sealing surfaces, especially well

tried in the chemical industry. |

Scope of Delivery : Scope of Delivery : |

|

| Standard dimensions according to table. Other dimensions on inquiry |

|

|