Fenzelit flexible bellows and expansion joints. Fenzelit flexible bellows and expansion joints. |

경험과

노하우 경험과

노하우

Frenzelit

공장은 설립된지 100년이 넘었고 항상 sealing과 절연을 위한 제품의 생산에 대하여 전문으로 삼았다. 오늘날 400명의 직원이 3개의

공장에서 근무한다.

Frenzelit는

50년대 중반에 복잡하고 신뢰할 수 없는 jointing 기술을 대신하여 첫 번째 팽창 joint를 만들었다. 40년 이상 동안 얻어진 경험은

고급 품질과 디자인의 신뢰, 제품의 선택과 팽창 joint의 조립을 보장한다.

Frenzelit의

광범위한 개발의 결과로써 비석면 팽창 joint의 생산을 위한 제품 기술은 특별히 인상적인 진보를 만들었다. 그러기 때문에 특별한 고급 합성

물질은 필요한 coating과 함께 우리가 만든 것이다.

높은

내구력 novaTEX/isoGLAS 격자무늬로 보강된 불소를 함유한(바이톤) 고무제품은 frenzelit 전문이다.

|

특성과

적용 특성과

적용

팽창

joint는 시스템 공학과 기계장치를 위한 연결 구성 뿐만 아니라 pipe line과 ducts의 영구적으로 구부러지기 쉬운 구조의 요소이다.

그들은 구부러지기 쉽고 증가되는 온도에 저항력을 가지고 있고 화학적으로 유동매개물에 저항력을 가지고 있고 압력과 진공상태 아래 안정된 저항력을

가지고 있다.

사용

중에 믿음을 지키는 동안, 비금속 팽창 joint는 시스템 구성요소 혹은 pipe line 그 자체와 같은 부하에 견뎌야 하고, 게다가 압력,

운전, 진동 혹은 축으로 그리고/옆면으로 진동을 흡수해야 한다.

비금속

팽창 joint에 대한 적용의 주된 범위는 뜨거운 공기, 유동 gas 또한 산성 혹은 알칼리성의 gas와 같은 기체의 매개물로 된

시스템이다.

|

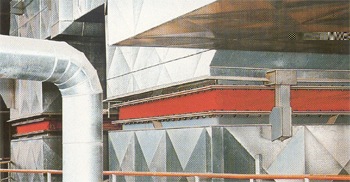

Steam

boiler system

발전소

가스

터빈 배기 장치

탈황

시스템

원자력

발전소

공업용의

노(爐) 건설

굴뚝

건설

쓰레기

소각로

건조

공장

열

공장

먼지

제거 system

환기와

통풍 sysetm

환풍기

건설

야금술의

공업: 규화물과 미세한 광물 등을 미세하게 만드는 공장

화학

공장

정제소,

석유 생산 기술

시멘트와

석회 공장

종이

산업

엔진

건설

|

|

|

각각의

제품 구성 각각의

제품 구성

산업의

시스템 공학에서 크기와 운영상의 조건은 너무 각각이기에 표준 팽창 joint를 제공할 수 없다. 그러기 때문에 frenzelit 팽창

joint의 제품의 중요한 점은 “치수를 재기 시작한” 제품이라는 것이다. 산업의

시스템 공학에서 크기와 운영상의 조건은 너무 각각이기에 표준 팽창 joint를 제공할 수 없다. 그러기 때문에 frenzelit 팽창

joint의 제품의 중요한 점은 “치수를 재기 시작한” 제품이라는 것이다.

몇가지

기본 디자인을 사용하여, 많은 다양한 변화는 적합한 합성물질, sealing films, foils과 coating의 선택을 가능하게 하고

구조와 조립의 디자인의 선택도 가능하게 한다.

원래

팽창 joint는 하나 혹은 그 이상의 물질의 층으로 구성되어 있다. 게다가 sealing film은 합성층과 주입에 의한 열과 기계적인 영향에

대비하여 보호되어 진다. 치수와 형태 뿐만 아니라 물질 선택과 적층 구조물은 특별한 적용에 따라 개별적으로 선택되어 진다. 모든 필요로 하는

연결 요소(철강 작업)는 또한 팽창 joint가 보충된다.

팽창

joint의 최적 디자인을 위한 가장 중요한 요구사항은 작동중의 설치크기, 압력, 온도, 운전에 관한 사용자의 기술 정보이다. 모든 중요한

요점을 상술하기 위해 frenzelit은 질문 사항에 응했다.

문의를

위해 이 팜플렛의 질문사항을 이용하길 바란다.

|

기술 안내 & 서비스 기술 안내 & 서비스 |

이

팜플렛의 포괄적인 안내는 우리의 팽창 joint 부분의 성능과 능력의 처음 효과를 단지 제공하기 위해 도와줄 수 있다. 요청에 입각해서, 우리는

우리의 완벽한 설명서를 포함해 당신에게 보내게 되면 기쁠 것이다. 이

팜플렛의 포괄적인 안내는 우리의 팽창 joint 부분의 성능과 능력의 처음 효과를 단지 제공하기 위해 도와줄 수 있다. 요청에 입각해서, 우리는

우리의 완벽한 설명서를 포함해 당신에게 보내게 되면 기쁠 것이다.

- 팽창

joint 질문 사항

- 팽창

joint의 모든 type의 각각의 도안

- 운반,

저장, 조립에 관한 지시

- Silicone

rubber를 위한 진행공정지시

- 특별한

접착제에 관한 정보

- 조립비율과

지시

|

개별적인

조언 개별적인

조언

어려운

적용을 위해 우리의 기술자들은 기술적인 단계 뿐만 아니라 당신의 기술적인 문제를 위해 충분한 획책을 얻기 위해 당신을 도울 것이다.

이것은

당신에게 편리하고 계획적인 해결책을 보증할 것이다.

우리의

인용 우리의

인용

당신의

data를 기초로 하여 상세한 계획을 포함하는 기술설명서는 편집되어졌다. 팽창 joint의 구조, 정밀한 측정, 비용과 운송날짜에 대한 정보를

함께 담고 있다. 만일, 가능하다면 우리는 양쪽 의견을 따를 것이다.

좀

더 정보를 위해 우리의 전문가를 이용할 수 있다.

팽창

joint의 설치 팽창

joint의 설치

당신의

안내와 감독의 형태로 도움을 선택할 수 있고 혹은 우리의 정비공에 의해 팽창 joint의 완벽한 설치를 선택할 수 있다. 당신의

안내와 감독의 형태로 도움을 선택할 수 있고 혹은 우리의 정비공에 의해 팽창 joint의 완벽한 설치를 선택할 수 있다.

일반적으로

팽창 joint의 완벽한 설치는 문제없이 당신의 숙련된 사원에 의해 실행 될 수 있다.

어려운

경우에 우리의 서비스 팀은 당신의 임의데로 쓸 수 있다.

설치

상태에 따라 팽창 joint는 쉬운 결합을 위해 준비된 끝부분에 대하여 열린 상태에서 공급되어진다.

원자력

공장의 팽창 joint 설치를 위해 우리의 직원은 효과적인 방사물 통과 법을 가지고 있다.

부속품 부속품

모든

필요한 부속품은 Frenzelit에 의해 공급되어진다. 당신의 요청에 따라 이 제품은 견적에 포함되어진다.

예를

들면 :

- Bolster(받침대)

: mineral wool, ceramic wool, silicate wool과 같은 그리고 또한 stainless

steel wire-cloth

- 우리의

기준에 따른 Pipe-clamps

- back-up(보완)

flange, duct flanges와 metal deflector plates(금속 변류기 판) 과 같은 steel 성분

- 접착성이

있는, 400/1000 타입들, hypalon, neoprene, silicone과 불소가 첨가된 고무

- 코팅된

물질과 seals

|

보증서 보증서

공급되는

각각의 팽창 joint에 대하여 Frenaelit는 보증을 제공한다. 보증서는 팽창 joint의 선택제품과 디자인에 따라 주어진다. 어떠한

보증서 요청도 당신의 요구에 포함되어진다. 당신의 data는 실제 운전 상태와 일치한다고 가정되고 조립과 진행공정은 응했다고

가정되어진다.

품질

관리 품질

관리

매번

Frenzelit 팽창 joint가 설치되어지는 것에 대하여 우리는 당신의 공장에 관한 책임을 분담한다. 이런 이유에 관하여 각각 제품과 공정의

품질은 꾸준한 관리를 받아야 한다. 제조된 팽창 joint는 엄격하게 조사되어진다. 매번

Frenzelit 팽창 joint가 설치되어지는 것에 대하여 우리는 당신의 공장에 관한 책임을 분담한다. 이런 이유에 관하여 각각 제품과 공정의

품질은 꾸준한 관리를 받아야 한다. 제조된 팽창 joint는 엄격하게 조사되어진다.

만일

요청한다면, 우리는 공사 인증서를 DIN 50049에 따라 공급한다.

TÜV

Essen과 밀접한 협력에서 1981년에 test절차에 대한 설명서는 승인되었다. 특별한 test 장비에 관해 변화하는 운전상태 아래 팽창

joint의 온도, 압력, 운전상태의 모의실험을 가능하게 한다. 이 팽창 joint를 위한 특별한 test는 첫 번째 단계 기량과 우리의 관리

시스템의 고급단계가 드러나는 원자력 발전소에 설치되어진다.

*증명을

위하여 아래의 예에 따라 code에 사용한 라벨은 각각의 팽창 joint에 부착된다.

RAL

품질 마크 RAL

품질 마크

Bavaria(TÜV)의

기술 검사 판으로부터 시험 보고서에 바탕을 두고 Frenzelit은 품질 협회 “구부러지기 쉬운 팽창 joint”의 구성원으로서 승인되어졌고

그들의 제품의 증명을 위하여 등록 권리에 의한 보호된 품질 라벨을 사용할 수 있는 권한을 부여했다. Bavaria(TÜV)의

기술 검사 판으로부터 시험 보고서에 바탕을 두고 Frenzelit은 품질 협회 “구부러지기 쉬운 팽창 joint”의 구성원으로서 승인되어졌고

그들의 제품의 증명을 위하여 등록 권리에 의한 보호된 품질 라벨을 사용할 수 있는 권한을 부여했다.

|

디자인의 기본 디자인의 기본 |

고정된

점 고정된

점

팽창

joint의 운전은 duct의 길이에 의존하고 팽창 joint에 관하여 고정된 점의 위치와 거리에 의존한다. 팽창 joint의 타입에 따라 큰

축성을 없애는 것이 가능하고 / 혹은 측면의 이동을 없애는 것이 가능하다. 팽창 joint의 내부 직경에 대한 측면 전치의 비율은 중요하다. 팽창

joint의 운전은 duct의 길이에 의존하고 팽창 joint에 관하여 고정된 점의 위치와 거리에 의존한다. 팽창 joint의 타입에 따라 큰

축성을 없애는 것이 가능하고 / 혹은 측면의 이동을 없애는 것이 가능하다. 팽창 joint의 내부 직경에 대한 측면 전치의 비율은 중요하다.

fabric

팽창 joint의 본래의 저항력은 대수롭지 않다.

보조 보조

예를

들면 pipe line의 제어된 움직임은 보조 혹은 slide point에 의해 가능하게 된다. 그들의 구조의 성질에 의해 강철 구성 요소로부터

부하는 피하게 되어진다.

|

운전 운전

길이에서

축의 변경 길이에서

축의 변경

팽창

joint가 조절할 수 있는 길이의 최대 거리는 몇 가지 요소에 따른다.

- type

혹은 윤곽에 대하여

- 가능한

설치 높이에 대하여 (팽창 joint의 소극적인 움직임은 설치 높이가 감소한다, 적극적인 움직임은 설치 높이가 증가한다.)

- 온도

상태에 대하여 그것은 내부의 insulation 필요성을 줄 수 있을지 모른다

|

측면의

전치 측면의

전치

게다가

길이에서 축의 변경은 또한 동시에 구부러지기 쉬운 팽창 joint를 측면 / 방사상 혹은 모서리의 움직임을 없앤다. 팽창 joint가 보정할

수 있는 측면 전치는 pipe line의 내부 직경에 의존하고 변류기 판 혹은 내부 절연의 필요성에 의존한다.

금속

변류기 판 금속

변류기 판

금속

변류기 판은 마모와 뜨거운 매개물의 직접 접촉으로부터 팽창 joint를 보호하기 위해 부착되어져 있다. 게다가 변류기 판은 duct 시스템에서

압력 손실을 최소화 한다. 상승되는 온도로 인하여 내부 insulation이 필요로 하는 곳이고 금속 변류기 판은 동시에 insulation

물질을 유지한다.

압력

기준 압력

기준

Frenzelit

팽창 joint는 압력과 진공을 위해 설계되었다. 새로운 고급 합성 품질 사용에 의하여 그것은 지속되는 높은 압력에 견딜 수 있도록 제조 설계가

가능하다. 압력 저항은 또한 중간 온도에 의해 영향을 받게 된다.

운전

온도 운전

온도

적합한

제품의 선택은 꾸준한 운전 온도의 레벨(수준)에 의해 넓은 범위까지 결정된다. 적합한

제품의 선택은 꾸준한 운전 온도의 레벨(수준)에 의해 넓은 범위까지 결정된다.

Frenzelit

fabric 팽창 joint는 -60℃정도(-76℉정도)에서 1200℃정도(2192℉정도)까지 광범위한 온도를 위해 설계될 수 있다.

상승하는

온도에 대한 저항력은 값 비산 제품이 되게 한다. 그러므로 당신의 요청에서 실제 작용 온도를 말해달라.

500℃정도(932℉정도)의

과도한 온도에서 내부 절연은 팽창 joint를 보호하기 위해 필요하다.

Type(유형)의

선택

당신의

system에 주어진 디자인과 팽창 joint의 요구되는 기술적 특성은 type의 선택에서 중요하다. Page 10에서 11의 도면은 가장

빈번하게 이용되는 type이다.

|

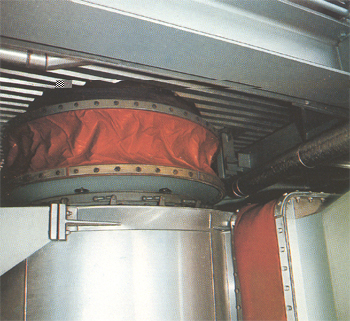

팽창

joint의 부착 팽창

joint의 부착

flange

없는 원형과 타원형의 형태는 pipe clamps에 부착될 수 있다. 압력, 온도, 직경에 따라 clamp는 우리의 표준 크기에서 부속품으로

공급되어진다. 점점 커지는 직경에 대하여 여러 부분 clamp는 증가되는 죄는(clamping) 힘을 제공하는데 익숙하다. flange

없는 원형과 타원형의 형태는 pipe clamps에 부착될 수 있다. 압력, 온도, 직경에 따라 clamp는 우리의 표준 크기에서 부속품으로

공급되어진다. 점점 커지는 직경에 대하여 여러 부분 clamp는 증가되는 죄는(clamping) 힘을 제공하는데 익숙하다.

fabric

flange로 된 선형과 직사각형의 팽창 joint는 느슨한 강철 flange에 부착되어 있다.

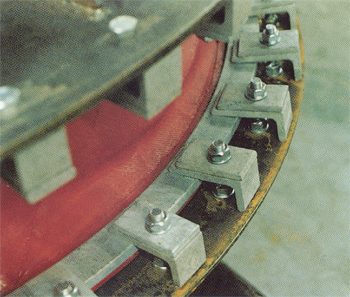

flange없는

직사각형 type은 clamping bar를 설치한다. 늘어진 flange의 폭과 두께는 팽창 joint의 제품 두께에 의해 결정된다. 팽창

joint의 손상을 피하기 위해 보완 flange와 clamping bar는 가장자리를 둘러싸거나 코너를 사각을 만들어야 한다. 나사머리는 항상

팽창 joint를 향한다: 볼록한 type 혹은 큰 움직임의 경우를 위하여 우리는 원추형 구멍을 파는 송곳 머리를 사용한 나사의 사용을

추천하였다.

나사

사이의 간격은 작용 압력, 팽창 joint flange의 두께와 복원 flange 혹은 clamping bar의 직경에 의존한다.

특별한

clamp를 사용한 팽창 joint 조립 - 가장 높은 것을 위한 연결은 견고함에 의존한다. 그러나 유지는 낮은 것에 의존한다.

이

자료는 frenzelit expansion joint 카다로그를 번역한 것이며 Design examples은 카다로를 참조하십시오.

|

Material characteristics Material characteristics |

The

purposeful combination of different material properties provides for and optimum

solution both technically and economically. High-grade and expensive special

materials are used only where it is a matter of enhanced safety or where loads

are extremely high. Otherwise the combination possibilities are determined by

the resistance of the materials to constant and peak temperatures, chemicals

and mechanical stresses.

The

material make-up of Frenzelit expansion joints is based on the following materials

Polyester

fabric

Carrier

fabric having high strength and abrasion resistance applicable up to 150 degr.

C

"novaTEX"

made from aramide fibre

especially

high strength, abrasion and friction resistant, good resistance to chemicals

"isoGLAS"

low-cost

substitutes with temperature resistance up to max. 450 degr. C

"isoTHERM

800"

from

finished filament yarns, reinforced with stainless steel wires. Resistant to

temperatures up to max. 800 degr. C

"isoTHERM

1000"

increased

resistance to temperatures owing to chemical conversion of the 6m fine mineral

fibres

Silicate

fabric

temperature

resistant to in excess of 1000 degr. C, outstanding resistance to chemicals

|

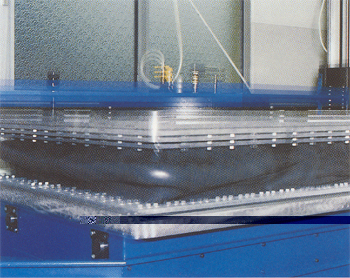

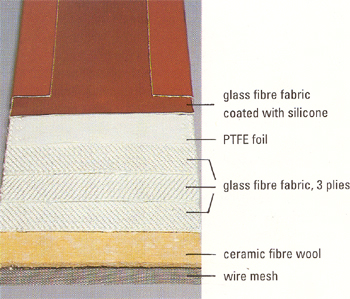

Lamination

of the material layers Lamination

of the material layers

The

layers of the expansion joint in front of the sealing foil serve mainly to protect

it from extremely high temperatures. The

layers of the expansion joint in front of the sealing foil serve mainly to protect

it from extremely high temperatures.

It

is only in vacuum that the material's tensile strength is subjected to stress.

Foils

embedded between the fabric layers act as actual sealing elements and also have

to withstand the temperature and medium load.

The

qualities available extend from neoprene (90 degr. C) to stainless steel (600

degr. C).

The

main function of the external fabric layer is to withstand the internal pressure'

a coating protects if from mechanical damage and aggressive environmental influences.

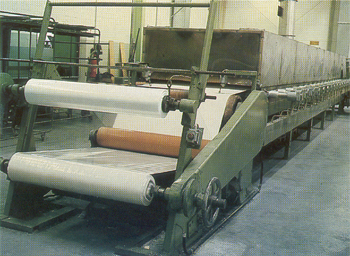

Various

quality grades of the fabric coatings are produced with special machinery. Only

in exceptional cases does the coating have a sealing function. For the majority

of Frenzelit expansion joints, the individual layers are glued together only

at the flanges. Various

quality grades of the fabric coatings are produced with special machinery. Only

in exceptional cases does the coating have a sealing function. For the majority

of Frenzelit expansion joints, the individual layers are glued together only

at the flanges.

This

ensures unhindered movement and guarantees high flexibility. In some cases however,

it may be necessary to apply adhesive on all layers covering their entire surface

area.

|

Pattern

carpenter's shop Pattern

carpenter's shop

In

the case of simple types of expansion joints the layers of material are laid

upon accurately dimensioned wood frames. In

the case of simple types of expansion joints the layers of material are laid

upon accurately dimensioned wood frames.

All

complicated forms require and original sized pattern which is individually produced

to the given measurements from wood or polystyrene in our own carpenter's shop.

Survey

of types Survey

of types

All

possible expansion joint types are shown on pages 10 and 11. The important distinguishing

features are.

- type

of flange (across page)

- shape

of the centre section and

- design

of the passage (vertical columns)

Even

where the drawings show only the circular expansion joint diameter, all types

can of course be produced with rectangular passage or with passages which change

from circular to rectangular.

|

|